I’ve found that making things out of wood requires many more tools than I had thought. I’ve continued to add tools to the collection, and still find myself constantly thinking of things that would further improve my work. I thought it would be fun to share some of the major parts of the shop with you.

I spend a lot of time standing between these two tables. The one with the peg board holds almost all my smaller hand tools and hardware. The larger table with the saw blade is where I put stuff together for glue ups or to sand them. The large filter with the red bucket is my dust collection system. This one is a bit of a Frankenstein system because I built it myself from many different brand name parts. Simply put, it’s a large vacuum for saw dust from the machines that I can hook up the machines to directly. The white pipes by the ceiling go to different parts of the shop and branch out to different tools.

This power tool cuts curves well. It also allows me to “resaw” a board in half the long skinny way giving me two boards of the same length and width, but about half the thickness. It is a great money saver when you can buy thick boards and turn them into more skinny ones.

This tool is a power sander that helps me get things smooth. The shelves hold all my glues and finishes.

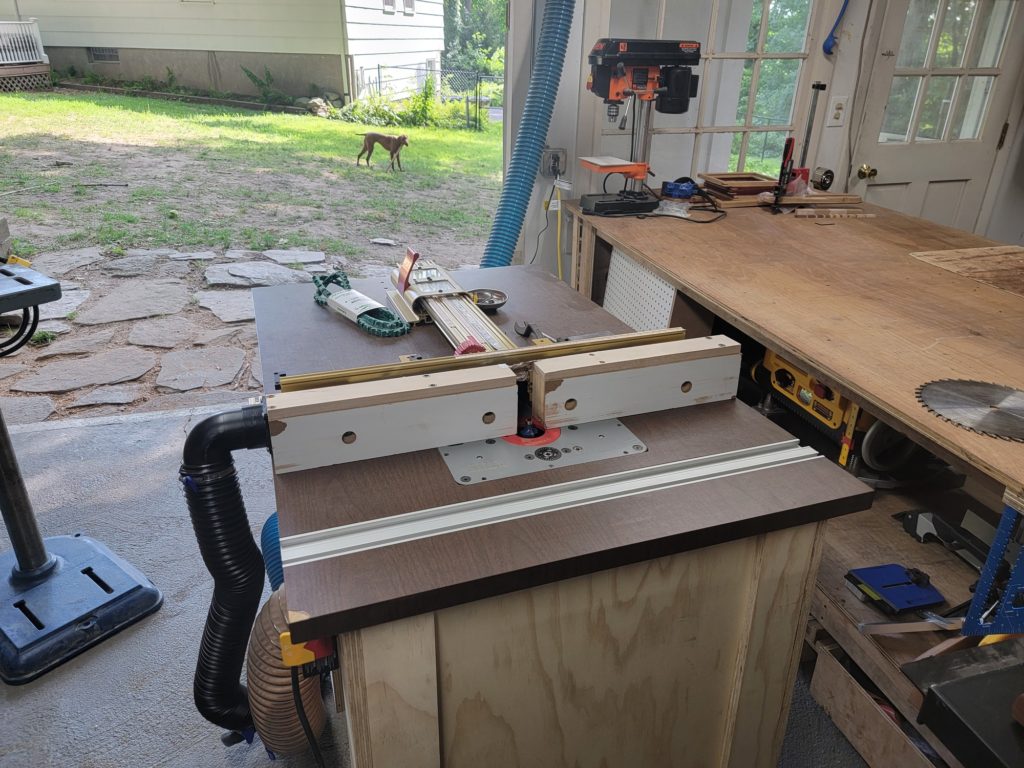

This table is for my router set up. A router is sort of like a drill, but instead of cutting down into things it cuts on the sides of the bit. If you look at nearly anything made of wood in your home, it has likely been routed. Examples include the designs on your kitchen cabinets, window sills, floor base boards, edges of your tables and chairs, ect. I use this to make edges rounded over or decretive.

This huge and heavy chunk of iron has one simple job: to make wood flat. Wood changes shape as it dries and because of this it is very hard to buy “ready to use” wood at the store. If you try to make something out of slightly curved or bowed wood, you’ll quickly find that the edges don’t meet and the wood doesn’t want to stay where you want it. Under the red guard is a terrifying cutterhead that spins and shaves off wood to flatten it out. It is very important when working with wood that you flatten the wood right before you start making something out of it.

The yellow box is a planer. It simply makes wood thinner. You could take a 1″ board and use this machine to plane it down to any thickness you want. It helps a great deal when you need multiple boards all the same thickness. The miter saw is something I don’t personally use as much. It’s a good tool for breaking large boards down into smaller more workable boards. I tend to do this with my table saw but mainly because I don’t have enough room to have a miter station in my shop.

This is one of the newest additions to my shop. These are often considered expensive luxury tools that most hobby shops wished they had but don’t want to spend the money on. It uses a powered conveyer belt to feed wood in and sand it with 2 drums of different sandpaper. It makes boards smoother and thinner at the same time while also producing a flat finished piece. This saves a ton of time in the finishing process by reducing hand sanding time. I would guess that this machine is able reduce the time it takes from start to finish on a cutting board by at least half.